紫外线激光打标机和雕刻机

品牌:SmartU

保修期:2年

免费采样,终身软件和免费更新,技术支持

UV Laser Marker & Engraver

Brand : SmartU

Warranty : 2 years

Free Sampling, Lifetime software and update freely, Technical support

The UV laser marking & engraving machine use laser beams to mark long-lasting marks on the surfaces of various materials. The marking effect is to directly break the molecular chains of substances through short-wavelength lasers to reveal the required etched patterns and text.

Ultraviolet laser is cold processing. This working method will not produce Heat, which is different from traditional laser.

Advantages of UV laser marking & engraving machine

Because the ultraviolet laser has a small focused spot and a small processing heat-affected zone, it can perform ultra fine marking and marking of special materials. It is a product chosen by customers who have higher requirements for marking effects. In addition to copper materials, UV laser is suitable for processing a wider range of materials. The marking speed is fast and the efficiency is high. The overall performance is very Stable, it is small with low power consumption.

Parameter

Model name | HT-UV3/HT-UV5/HT-UV10 |

Laser power | 3W/5W/10W |

Laser wave length | 355nm |

Frequency | 1-00KHz |

Marking area | 110X110mm145X145mm(optional) |

Engraving depth | ≤0.4mm(It depends on the material) |

Marking speed | ≤7000mm/s |

Mini line width | 0.01mm |

Mini character | 0.1mm |

Repeated accuracy | ±0.1mm |

Power supply | AC220V/Singlephase/50Hz |

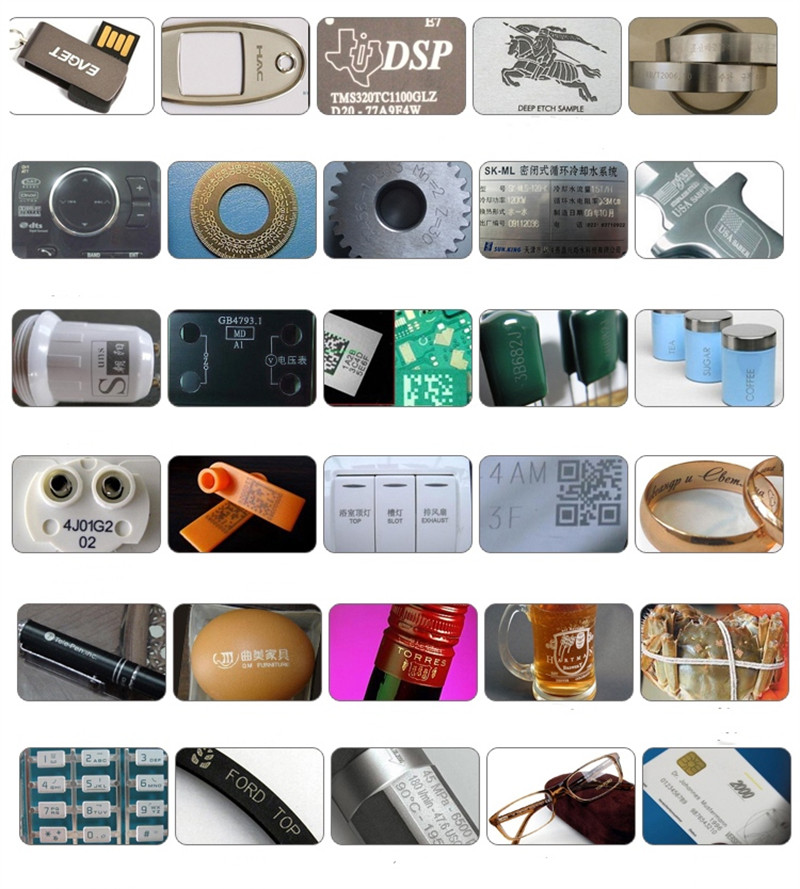

Application of UV laser marking & engraving machine

With its unique low-power laser beam, the UV laser marking machine is especially suitable for the high-end market of ultra-fine processing, such as surface marking of packaging bottles of cosmetics, medicines, videos and other polymer materials. The effect is fine and the mark is firm, better than ink jet coding and pollution-free; flexible PCB board marking and scribing; silicon wafer micro-hole and blind hole processing; LCD liquid crystal glass QR code marking, glassware surface drilling, metal surface coating marking, Plastic buttons, electronic components, gifts, communication equipment, building materials, etc.

Working environment

The ambient temperature is required to be between 15-30℃.

The humidity requirement is 40%-80%. No condensation.

Pre-sales and After-sales

1. Before official PO, we can provide various production process plans, technical consultation, sample testing, equipment selection and other services for laser equipment.

2. We provide free technical training. After installation and debugging, technical training documents will be provided to the buyer's operators.

3. The company promises to provide two years of free warranty.

4. Customer service response time is within 24 hours.

5. When the equipment warranty period expires, technical support will be provided for whole life, and only the cost of accessories will be charged.

6. Extensive software and hardware support will still be provided after the warranty expires.

Samples reference

联系人:selena

手机:+86 18098979853

电话:+86 18098979853

邮箱:selena@smartu-tech.com

地址: Building A, Sihai Yunchuang Building, Hou Ting community, Sha Jing Street, Bao An district, Shen Zhen, Guang Dong of China. Post code: 518104