When it comes to industrial processes like laser etching and laser marking parts or materials with identification or alphanumeric codes, two related but distinct methods, laser engraving and laser marking are popular. While these two methods might look identical to some, they differ subtly in their application, materials, and finished results. Here, we’ll dive into the differences between laser engraving and laser marking to help you determine which is the most suitable method for your products.

Firstly, let’s see how Laser engraving and laser marking work.

Laser engraving involves using a high-powered laser to cut or burn the surface of a material, creating an indentation or pit on the surface, removing material with considerable heat leaving a cut into the substrate usually quite deep. The laser beam melts the top layer of the material and removes it from the underlying layer. The result is a deep, permanent recessed marking that lasts for the entire lifetime of the product since it goes beneath the superficial first layer. This method works best with metals, hard plastics, and other materials that can endure high temperatures. Laser engraving applications in industrial sectors include marking of medical surgical instruments, aerospace parts, firearms, automotive components, and many more.

Laser marking, on the other hand, uses a low-powered laser to create a darker-colored or colored hue on the top surface of an object without causing comprehensive burn or melting of the material. The energy from the laser causes a reaction between the surface atoms and the marking media used, such as paint or ink, producing an image, logo, text, barcodes, QR codes, and alphanumeric codes on the surface. The result is a high-contrast, high-resolution marking that can be applied on most surfaces, including metals, plastics, ceramics, glass, and even fabrics. Laser marking applications in industrial sectors include medical device marking, electronics and semiconductor marking, automotive and aerospace part marking, and jewelry marking.

Secondly, let’s see the cost and time differences between laser engraving and laser marking.

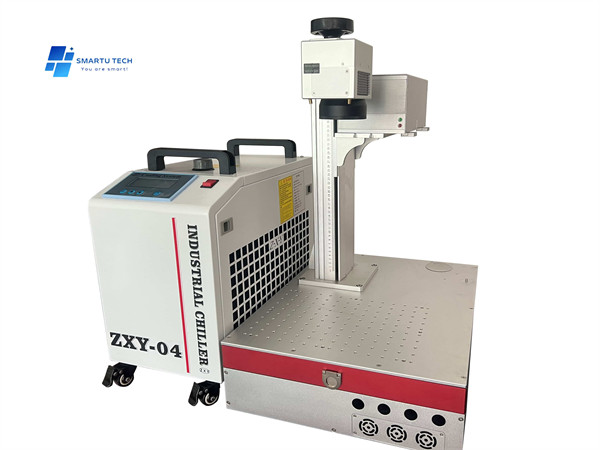

Another significant difference between laser engraving and marking is the cost of equipment and time. Laser engraving requires a higher-power laser and more extended processing time, making it a more expensive process. Laser marking machines have a lower wattage and require less processing time, making it a faster, more economical marking process. Since laser marking can be used on numerous materials, there is no need for additional equipment like CNC machines, making it suitable for smaller quantities which would otherwise not be viable due to high setup costs.

Thirdly, let’s see the contrast and accuracy differences between laser engraving and laser marking.

Laser engraving has a more consistent contrast since it’s etched beneath the surface and is generally more accurate on smaller details than laser marking. Also, laser engraving is suitable when your products need to have exact depth or raised features. In contrast, laser marking is best for highly detailed prints that require less depth and better visibility. The contrast on the surface marking is more susceptible to the surface color of the material.

In conclusion, deciding on the right method, laser engraving or laser marking, depends on your specific industrial application requirements. If your products require permanency and durability and can handle high heat, laser engraving is suitable for you. If, however, you need a faster, economical, and high-resolution marking that doesn’t penetrate deep into the material surface, laser marking is the way to go. We recommend discussing your needs with a professional material marking company like us SmartU tech, to help you determine the best method for your needs.

Contact: selena

Phone: +86 18098979853

Tel: +86 18098979853

Email: selena@smartu-tech.com

Add: Building A, Sihai Yunchuang Building, Hou Ting community, Sha Jing Street, Bao An district, Shen Zhen, Guang Dong of China. Post code: 518104