Handheld laser welding machine

Brand : SmartU

Laser Power :1000W/1500W/2000W/(can be customized)

Warranty : 2 years

Free Sampling, Lifetime software and update freely, Technical support

Handheld laser welding machine

Brand : SmartU

Laser Power :1000W/1500W/2000W/(can be customized)

Warranty : 2 years

Free Sampling, Lifetime software and update freely, Technical support

The handheld laser welding machine uses a continuous fiber laser as the light source. It has many new ideas in terms of equipment appearance, structure and human-machine interface suitable for operation based on humanization and work effectiveness. The handheld welding head can be customized according to actual production and is very suitable for non-standard production. It is water-cooling and does not get hot during long-term welding. It has a small diameter and easy to hold by hand. At the same time, it fully considers the various parameters of the equipment in mass production. The key parameters can be adjusted and the data can be displayed.

Parameter

Brand | SmartU | ||

Laser Power | 1000W | 1500W | 2000W |

Power Stability | ±2% | ||

Laser Wave length | 1064nm | ||

Laser Mode | Continuous&Pulsed | ||

Fiber length | 5-10m | ||

Pulse Frequency | 1~2500Hz | ||

Welding thickness | 0.5-3mm | ||

Power Consumption | ≤7KW | ≤9KW | ≤11KW |

Power Supply | AC220V±10%50/60Hz single phase | ||

Locating System | red laser assistance | ||

Flexible Worktable | support co-work with robot arm | ||

Cooling Method | Independent Water Cooling | ||

Welding requirements | ≤0.4mm | ||

Welding speed | 0-120mm/s | ||

Ambient Environment | temperature15~35C, humidity≤70% without condensation | ||

Features of handheld laser welding machine

■ The laser has long service life, high electro-optical conversion efficiency, low maintenance cost, simple and easy to operate.

■ Compact design and built-in water cooling technology ensure the smallest floor space and maximum mobility.

■ Available in 1000W and 1500W. Two options adapt to the welding depth and efficiency requirements of different materials.

■ Can achieve penetration welding of 3mm stainless steel or high-speed welding of 1mm stainless steel

■ Standard water-cooled blowable welding head; optional swing welding head can achieve a maximum welding spot of 4mm. Especially suitable for situations where the weld seam is too wide or the weld seam is irregular.

■ The welding surface will be smooth and bright, and can be welded repeatedly. It only needs to be lightly polished after welding. It is also possible to weld stainless steel without polishing by blowing argon gas when welding stainless steel.

■ Three different copper nozzle can be adapted Internal fillet welding, external fillet welding, splice welding and other applications.

Application of handheld laser welding machine

Sheet metal processing, advertising signs, commercial kitchen custom processing, stainless steel stoves, barbecue cars, dining cars, doors, windows, fences, stainless steel furniture and lamps, distribution boxes, equipment cabinets, and pipe welding. Suitable for stainless steel, titanium plated plate, galvanized plate, white iron, titanium steel plate, colored plate, copper plate, aluminum plate and other metals.

Several common welding methods of handheld laser welders

First, let’s talk about the welding between boards, which is basically divided into four types: tailor welding, side welding, penetration welding, and spot welding.

Next is the welding of wires, which is also divided into four welding methods: butt welding, cross welding, parallel tower welding, and T-shaped welding.

There is also the welding of wires and block components. At present, laser welding can realize the welding of electronic devices and metal wires.

As for the welding of dissimilar metals and welding of different materials, laser welding technology is more dominant, especially stack welding, but not all materials can be welded to each other.

Cooling system installation requirements of Laser welding machine

1. Cooling system water temperature setting:

Water cooler 22±1℃ (no need to change in summer)

2. Coolant requirements:

The cooling water is purified water, and it is recommended to use purified drinking water.

In order to prevent mold growth in the water in the chiller from causing pipe blockage, it is recommended to add ethanol when filling purified water. The volume ratio of ethanol is 10%.

When the ambient temperature of the equipment is between -10°C and 0°C, an ethanol solution with a volume ratio of 30% must be used and replaced every two months.

When the ambient temperature around the equipment is lower than -10°C, a dual-system chiller (with heating function) must be used to ensure uninterrupted operation of the cooling system.

3. Other requirements for cooling system:

When starting the cooling system for the first time, check the entire water system and joints for leaks.

External water pipes must be installed and connected according to the water inlet (IN) and water outlet (OUT) marked on the laser, otherwise the laser may not work properly.

If the laser is not used for a long time, the cooling water inside the cooling system and the laser should be drained, otherwise the laser will be irreparably damaged.

Application reference

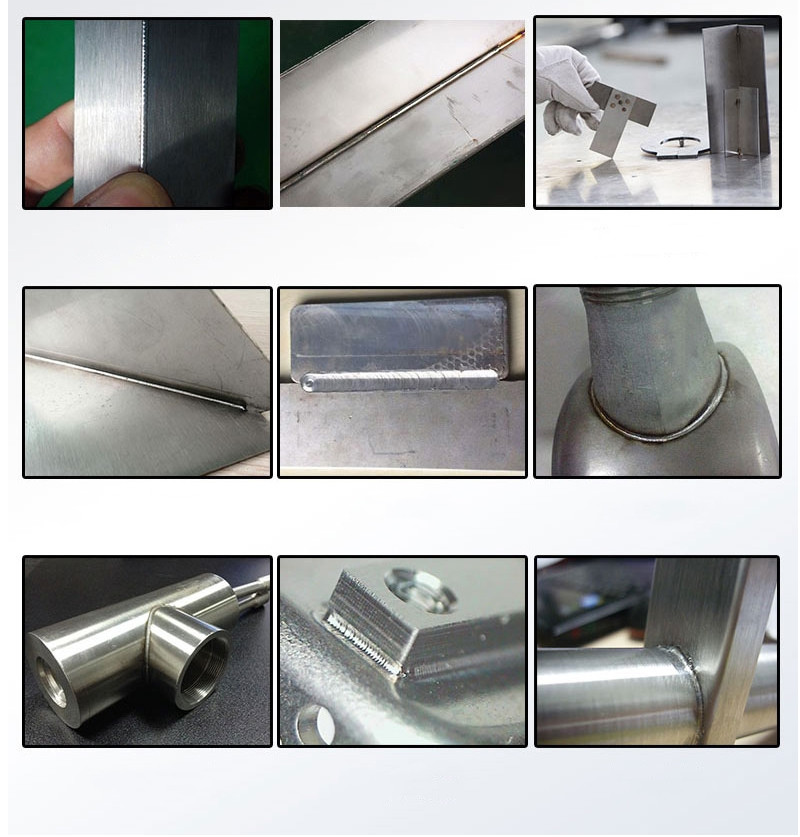

Samples reference

Contact: selena

Phone: +86 18098979853

Tel: +86 18098979853

Email: selena@smartu-tech.com

Add: Building A, Sihai Yunchuang Building, Hou Ting community, Sha Jing Street, Bao An district, Shen Zhen, Guang Dong of China. Post code: 518104